In the face of mounting climate change challenges and the pressing need for cleaner and more sustainable energy alternatives, the growing impetus towards green hydrogen offers a ray of hope. This remarkable form of hydrogen, generated through the process of electrolysis by tapping into renewable energy sources, holds transformative potential across industries, shaping a future that is both environmentally responsible and resource-efficient.

What Is Green Hydrogen Used For?

Green hydrogen, aptly dubbed for its eco-friendly production process, stands poised to fulfill its longstanding potential as a clean energy solution. It is the need of an hour to harness the power of hydrogen and drive the era of clean, secure, and affordable energy. However, the crux of the matter lies in understanding how green hydrogen can expedite this transition. What can green hydrogen derivatives be used for? So, let’s delve into the manifold uses of green hydrogen to unravel its potential.

Uses of Green Hydrogen in Various Industries

Green hydrogen is emerging as the promising solution to transform hard-to-abate sectors like refining, maritime shipping, fertilizers, and methanol production. Here is a thorough analysis of green hydrogen uses across various industries.

Refining Petroleum and Treating Metals

Green hydrogen finds its place in industries that rely heavily on hydrogen for their processes. One such industry is petroleum refining. Hydrogen is used to remove impurities from crude oil and convert it into usable fuels. By substituting conventional hydrogen with green hydrogen, the carbon footprint of the refining process can be significantly reduced.

Similarly, the metals industry utilizes hydrogen for various applications, such as annealing, sintering, and reducing metal ores. Green hydrogen can help reduce emissions associated with these processes, making the production of metals more environmentally friendly.

Power Generation

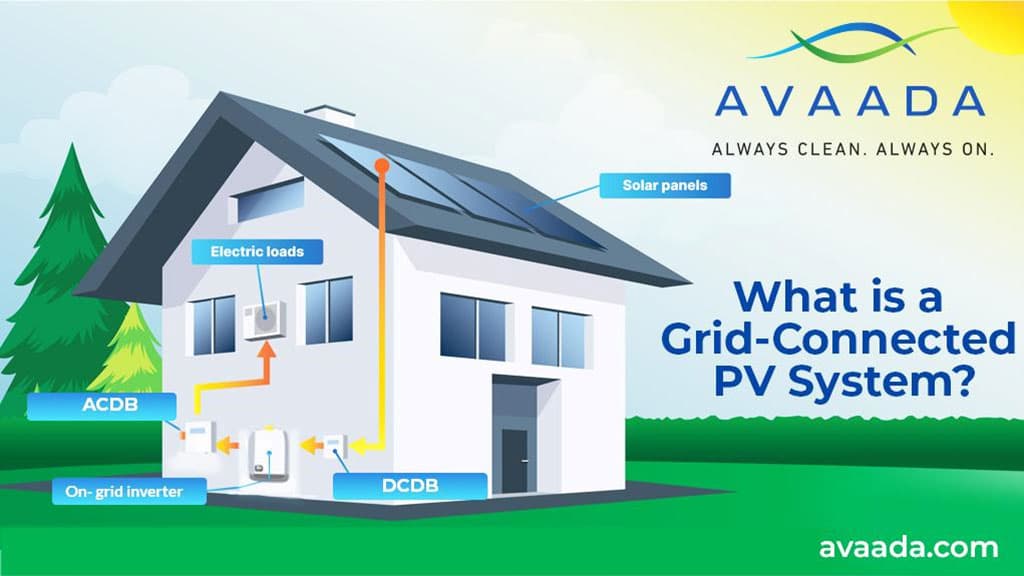

The potential uses of green hydrogen also include electricity generation. Fuel cells combine hydrogen with oxygen from the air to produce electricity and water with no harmful emissions. This technology holds great potential for clean power generation, especially in sectors that are difficult to electrify directly, such as heavy industries and long-haul transportation.

Transportation

The transportation sector is a significant contributor to greenhouse gas emissions. Green hydrogen can play a transformative role here by powering fuel cell vehicles. These vehicles emit only water vapor and heat, offering a clean alternative to internal combustion engine vehicles. Green hydrogen can also be used to fuel ships and airplanes, helping reduce emissions in these hard-to-decarbonize sectors. The demand for hydrogen could grow by almost 400 percent by 2050, led by industry and transportation if the prices decline.

Chemical Industry

Hydrogen is used as a key feedstock in the chemical industry to carry out various processes like ammonia production and methanol synthesis. Green hydrogen can replace conventional hydrogen sources, thereby reducing the carbon footprint of these chemical processes.

Also Read: Green Hydrogen VS Blue Hydrogen

Green Hydrogen: Sustainable Path into the Future

The promise of green hydrogen as a cornerstone of our future energy landscape is garnering substantial attention. The global appetite for hydrogen has surged, reaching around 87 million metric tons in 2020, and is poised to skyrocket to an estimated 500–680 million metric tons by 2050.

This exponential demand surge has catalyzed approximately 43 nations to map out strategic pathways toward establishing a hydrogen-centric economy. These endeavors encompass strategic financial incentives aimed at expediting the transition to hydrogen-based energy solutions.

This trajectory closely aligns with India’s vision of fostering a low-carbon economy, reinforcing energy security, and nurturing comprehensive economic progress.

The international landscape is now witnessing a fresh surge of growth across nations. A resurgence of interest in green hydrogen production technologies is evident, with Europe and the U.S. leading a burgeoning movement.

In India alone, the demand for hydrogen is projected to surge more than fourfold by 2050, constituting nearly 10% of the global hydrogen demand. Established sectors, such as refineries, ammonia production, and methanol synthesis, are already reliant on hydrogen as a key industrial input. These industries will embrace the use of green hydrogen.

India’s ambitious target of producing 55 million tonnes of green hydrogen by 2050 underpins its dedication to sustainable energy. This vision is being supported by the launch of the National Green Hydrogen Mission, aimed at facilitating the transition from fossil fuels and feedstocks to renewable alternatives based on green hydrogen.

A notable player in this transformative journey is the Avaada Group, a prominent industry player steering the clean energy transition. The organization brings together various prominent technological developments encompassing India’s power grid and renewable resource bank to drive successful penetration of green hydrogen.

The group recently concluded a substantial funding round, amounting to Rs 10,700 crore ($1.3 billion), which is a pivotal achievement for India’s renewable energy sector. These funds will invigorate Avaada’s endeavors in green hydrogen, green methanol, green ammonia, solar panel manufacturing, and renewable power generation.

This strategic step echoes the effectiveness of government policies that foster investments in sustainable energy, further propelling the global shift towards a greener energy landscape.

Also Read: Different Types Of Electrolyzers

Frequently Asked Questions About Green Hydrogen Uses

1. What are green hydrogen uses?

Green Hydrogen, heralded as a revolutionary advancement find potential application across various industries such as refining, maritime shipping, fertilizers, methanol production, and other hard-to-abate sectors known for their substantial carbon emissions.

2. What is the difference between green hydrogen and gray hydrogen?

Green hydrogen is produced using renewable energy sources, while gray hydrogen is typically produced from natural gas through a process called steam methane reforming, which emits carbon dioxide.

3: Can green hydrogen completely replace fossil fuels?

Green hydrogen has the potential to significantly reduce our reliance on fossil fuels and decarbonize hard-to-abate sectors. In the future, the cost of green hydrogen is expected to decline dramatically, which will further boost the drive toward achieving complete decarbonization.