Solar panels are essential components of renewable energy systems, converting sunlight into electricity through advanced technologies. The manufacturing of solar panels involves a series of intricate steps that turn raw materials into durable, efficient photovoltaic (PV) modules that power homes, industries, and large solar farms. Let us explore in detail the solar panel manufacturing process, highlighting advancements and industry practices with an example of a major Indian manufacturer.

Introduction to Solar Panel Manufacturing Process

The solar panel manufacturing process involves transforming raw materials into photovoltaic (PV) modules that convert sunlight into electricity. This process includes multiple stages, including silicon purification, wafer fabrication, cell production, module assembly, and quality testing. The demand for higher-efficiency, higher-wattage solar panels continues to drive innovation in the manufacturing sector. Avaada in India specializes in producing advanced high-wattage modules with capacities exceeding 700 watts, meeting the growing needs of utility-scale solar projects.

Key Steps in How to Manufacture Solar Panels

The manufacturing of solar panels is a complex, multi-stage process that transforms raw silicon into efficient, durable photovoltaic modules capable of generating clean energy.

1. Silicon Purification and Ingot Formation

The process begins with extracting silicon from quartz sand, which is then purified to achieve semiconductor-grade purity. This refined silicon is melted in high-temperature furnaces and formed into cylindrical ingots using the Czochralski process. The ingots are then sliced into thin wafers with specialized saws. These wafers, essential substrates for solar cells, must be uniformly thin and free from defects to ensure optimum performance.

2. Solar Cell Manufacturing

The silicon wafers are cleaned and etched to prepare the surface. Doping introduces impurities, such as phosphorus or boron, to create a positive-negative junction, enabling electron movement when exposed to sunlight. An anti-reflective coating is applied to reduce sunlight reflection and increase absorption. Metal contacts are added to both sides of the cell to collect the generated electrons efficiently. Modern cell technologies, such as the n-type TopCon process, known for its efficiency and longevity, are widely used by manufacturers to produce premium solar cells.

3. Module Assembly

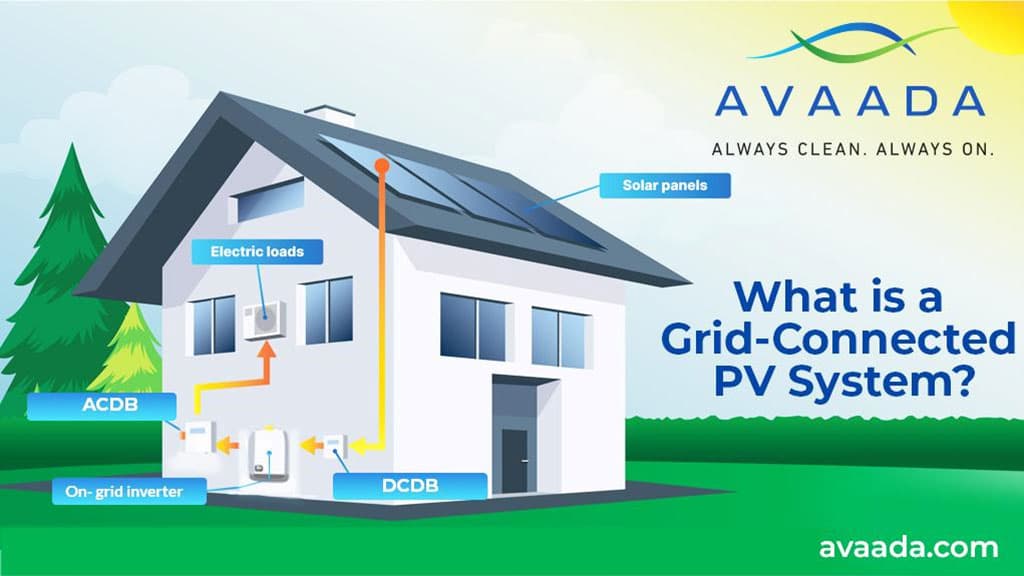

Solar cells are interconnected in series and parallel arrangements to achieve the desired voltage and current output. These interconnected cells are sandwiched between tempered glass on the front and a protective backsheet, bound together with an encapsulant such as EVA (ethylene-vinyl acetate) through a lamination process. Frames are added to provide structural integrity, and junction boxes are installed for electrical connections. This phase often incorporates automation and robotics to ensure precision and reliability.

4. Quality Control and Testing

Each solar panel undergoes exhaustive testing focused on electrical output, resistance to environmental factors like moisture and temperature fluctuations, and mechanical strength. Certifications such as IEC, BIS, UL, and TUV validate compliance with national and international standards. Manufacturers also prepare for evolving regulations, such as India’s Domestic Content Requirement (DCR) and the Approved List of Models and Manufacturers (ALMM), ensuring compliance with market access and government incentive requirements.

Strict quality control and adherence to evolving standards ensure that the finished solar panels perform reliably and meet market and regulatory requirements for sustainable energy deployment.

Each solar panel undergoes exhaustive testing focused on electrical output, resistance to environmental factors like moisture and temperature fluctuations, and mechanical strength. Certifications such as IEC, BIS, UL, and TUV validate compliance with national and international standards. Manufacturers also prepare for evolving regulations, such as India’s Domestic Content Requirement (DCR) and the Approved List of Models and Manufacturers (ALMM), ensuring compliance with market access and government incentive requirements.

Strict quality control and adherence to evolving standards ensure that the finished solar panels perform reliably and meet market and regulatory requirements for sustainable energy deployment.

Importance of Solar Panel Manufacturing in Delhi and Across India

Delhi, being a central hub for policy and trade, plays an important role in the solar panel manufacturing supply chain through initiatives, market demand, and distribution infrastructure. While large manufacturing plants are primarily situated in states like Gujarat and Maharashtra, Delhi’s market includes solar panel distribution, installation, and renewable energy consultancy. The push toward domestic manufacturing, supported by policies such as Atmanirbhar Bharat, strengthens the solar panel manufacturing ecosystem across India, including Delhi, stimulating local industry growth and job creation.

Conclusion

The solar panel manufacturing process is complex and involves several critical steps from raw material processing to final quality testing. Avaada exemplifies advancements in manufacturing with its high-wattage modules, integrated facilities, and focus on proven technology. Understanding how solar panels are manufactured clarifies the significant effort required to produce efficient, reliable, and environmentally friendly energy solutions. India’s solar manufacturing ecosystem, connecting production across states and markets such as Delhi, supports the nation’s renewable energy goals and its global clean energy commitment.

FAQs

How are solar panels manufactured step by step?

Solar panels are manufactured through a multi-stage process that includes silicon purification, ingot and wafer formation, solar cell production, module assembly, lamination, framing, and final quality testing to ensure efficiency and durability.

What raw materials are used in solar panel manufacturing?

The primary raw material used in solar panel manufacturing is high-purity silicon derived from quartz sand. Other essential materials include tempered glass, EVA encapsulant, backsheet films, aluminium frames, and conductive metals such as silver and copper.

What is the role of silicon in solar panel manufacturing?

Silicon acts as a semiconductor in solar panels, enabling the conversion of sunlight into electricity. Its crystalline structure allows electrons to move when exposed to sunlight, generating an electrical current through the photovoltaic effect.

How are solar cells different from solar panels?

A solar cell is the basic unit that converts sunlight into electricity. In contrast, a solar panel (or module) is made by electrically connecting multiple solar cells and enclosing them in protective layers to produce usable power.

What is n-type TOPCon technology in solar panel manufacturing?

N-type TOPCon (Tunnel Oxide Passivated Contact) is an advanced solar cell technology that reduces energy losses, improves efficiency, and enhances long-term performance compared to conventional p-type solar cells.

How long does it take to manufacture a solar panel?

The complete solar panel manufacturing process typically takes several days, depending on production scale, automation level, and quality testing procedures, with most time spent on silicon processing and cell fabrication.

Why is quality testing important in solar panel manufacturing?

Quality testing ensures that solar panels meet electrical performance standards, withstand environmental conditions, and comply with certifications such as IEC, BIS, UL, and TUV for safe and reliable long-term operation.

What is the Approved List of Models and Manufacturers (ALMM)?

ALMM is a government-mandated list in India that includes approved solar panel models and manufacturers eligible for use in government-supported and utility-scale solar projects.

Where are solar panels manufactured in India?

Solar panels in India are primarily manufactured in states such as Gujarat, Maharashtra, Rajasthan, and Tamil Nadu, with distribution, installation, and policy coordination supported by markets like Delhi.

Why is domestic solar panel manufacturing important for India?

Domestic solar panel manufacturing reduces import dependence, strengthens energy security, supports government initiatives such as Atmanirbhar Bharat, and accelerates India’s transition to clean, sustainable energy.